Laboratory of Energy Performance in Compressed Air System (CAS)

Introducing LABAC

The Lab was born with the aim of studying CAS from a multidisciplinary energy perspective (both simulating and testing).

Compressed air is a clean and safe – but low efficiency – energy carrier whose optimal production transmission distribution and use requires many-fold expertize.

The scope of the Lab is to make the students available with the opportunity to know more about it: not only the principles and the applications, but also how to characterize it from an energy standpoint.

Regulation of the Lab.

Location: the Lab is located at the A floor, DIII, Via Ferrata 5 – 27100 Pavia (Italy).

Equipments

- COMPRESSOR: ATLAS COPCO GA30

Atlas Copco rotary screw air compressor is a lubricated machine, air-cooled version (with radial speed fan) and conform with the ISO 1217, ed.3, Annex C (1996) test code. Elektronikon (r) control. Totally enclosed fan-cooled (TEFC), IP55, class F electrical motor. Gear drive, flexible coupling (Technical Data Sheet).

- DRYER

A compressed air dryer is a device for removing vapor from compressed air. Dryers are commonly found in a wide range of industrial and commercial facilities.

The process of air compressing concentrates atmospheric contaminants, including water vapor. This raises the dew point of the compressed air relative to free atmospheric air and leads to condensation within pipes as the compressed air cools downstream of the compressor (Technical Data Sheet).

- FILTERS

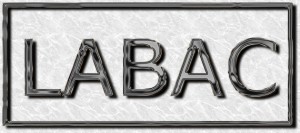

- PIPELINE

Layout of the Pipeline (Technical Data Sheet).

- MEASUREMENT INSTRUMENTS

Umidity transmitter, Pressure transmitter, Vortex flowmeter, Thermal mass meter.